How Prime Inc. optimized tire recycling with EASE and GeneXus

Discover how one of the largest transportation companies in the United States optimized its tire recycling division using the EASE software developed with GeneXus, achieving operational efficiency and environmental sustainability.

Prime Inc., one of the largest transportation and logistics companies in the United States, faced a growing challenge: efficiently managing the recycling of used tires generated by its vast fleet. To address this, it created EcoShred, an internal division focused on responsible recycling. But the real transformation came with the implementation of the EASE system, developed with GeneXus, which enabled full automation of EcoShred’s logistics, traceability, and operations. The result: efficiency, cost reduction, sustainability, and scalability.

To tackle this environmental challenge, Prime created EcoShred, a division dedicated to tire recycling. Its highly technical process includes:

This process turns waste into reusable products such as:

The machinery worked. The bottleneck was in the logistics management system. EcoShred coordinated tire collections using spreadsheets and whiteboards. The lack of real-time visibility and the high probability of human error hindered growth.

“It was a slow system, prone to errors, and difficult to scale. We needed a more efficient way to work,” explains Michael Jones, EcoShred Manager.

EASE (Enterprise Automated Support Environment) was already successfully operating in EcoTire, Prime’s retreading unit, where between 35,000 and 40,000 tires are remanufactured annually, extending their lifespan up to 100,000 miles (160,000 kilometers).

But about 20% of tires are not suitable for retreading. That’s where EcoShred comes in - and where EASE proved its versatility.

“Now we see everything on a single screen, in real time. We don’t waste resources or money. We generate less waste, reduce costs, and save energy,” says Michael Jones.

EASE is a living, scalable platform deeply adaptable to each client's specific needs. And that’s made possible by GeneXus - the technology that has transformed how Information Services Select designs and delivers business solutions.

“With EASE managing these core activities, we can expand the platform more efficiently, adding customized functionalities that address specific business needs. The result is a highly tailored, cost-effective product focused on real value for the client,” explains James Reed, Director of Information Services Select.

Another remarkable aspect of EASE is that it was built by just two developers: one handled the core system functions, and the other expanded those foundations and created custom modules for different clients.

Today, over 1,000 users log into EASE daily, most from within the client environments themselves.

“Having a product like EASE lets me focus on the creative side, without diving into the technical details of every solution. For the client, that translates into a platform that allows them to focus on what really matters: growth, opportunities, and profitability,” says Reed.

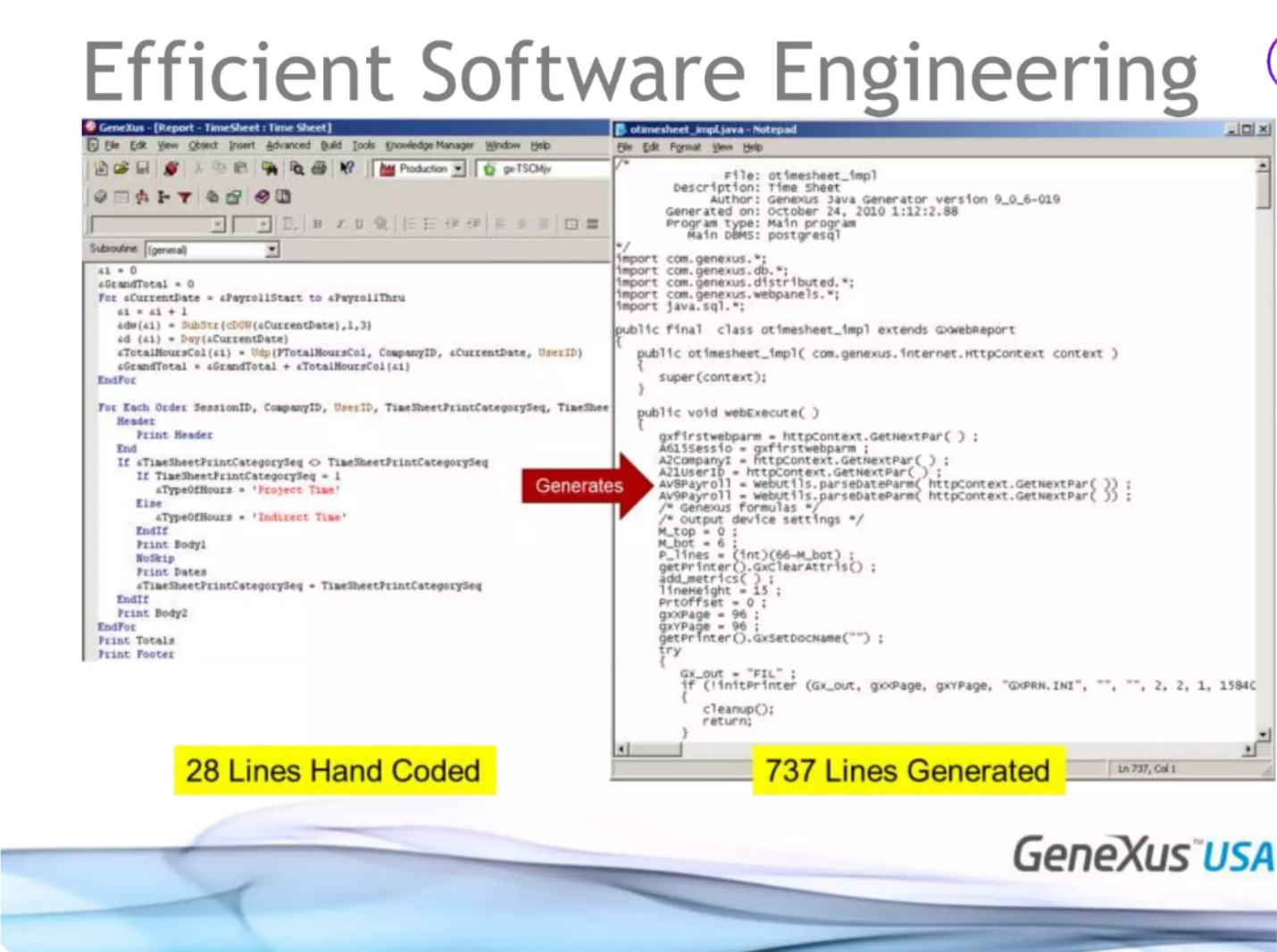

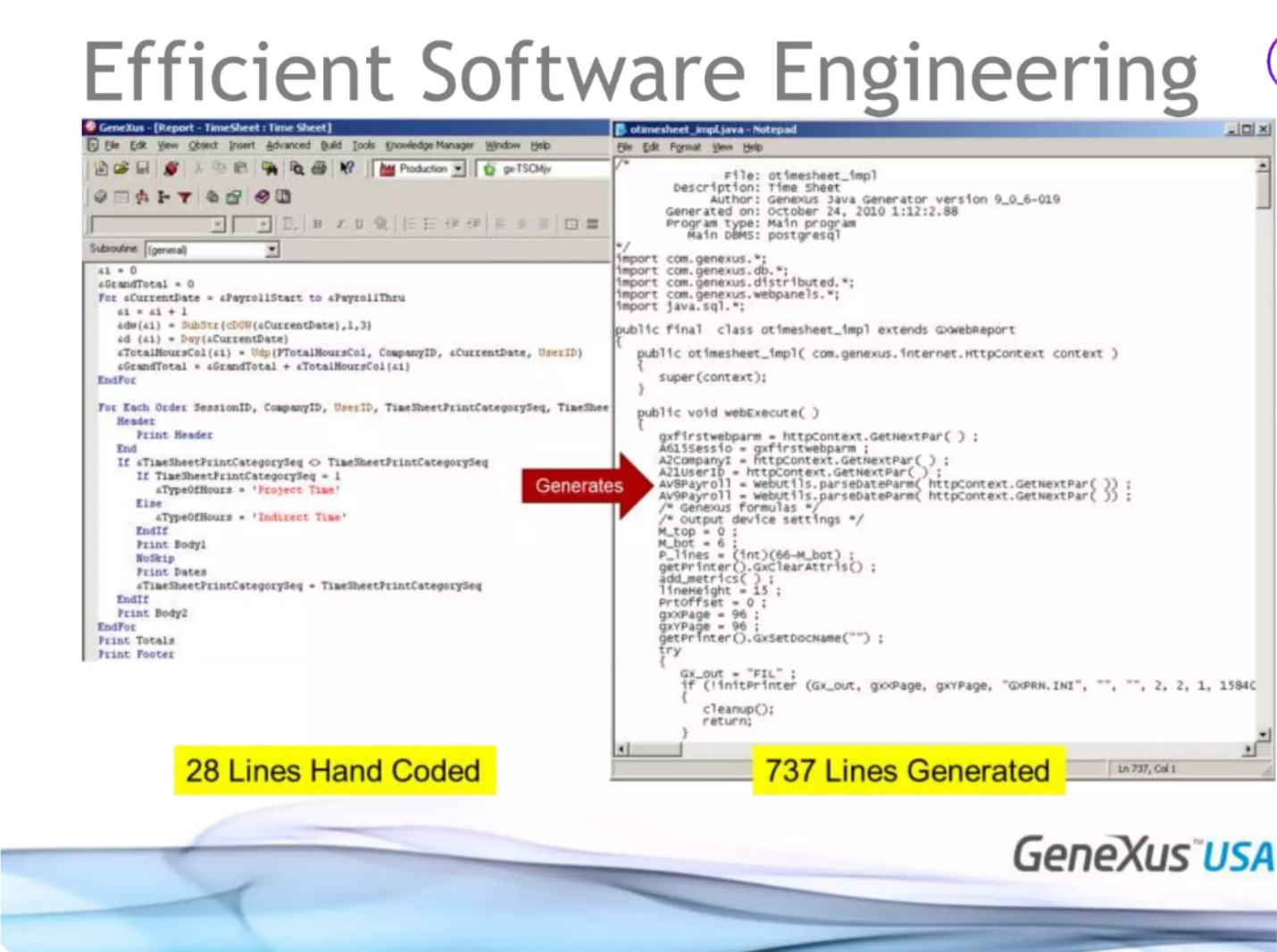

At a developer conference held in Chicago, Reed shared a striking example: 28 lines of GeneXus code equaled over 737 lines of native Java. Less code, more functionality - a quantum leap in efficiency.

“Back in 1991, I was looking for a tool to prototype what a client wanted, without spending weeks on something that might not get approved. I was introduced to GeneXus for its ability to generate functional prototypes that could be directly turned into real products. It was clear that it should be our platform for both prototyping and production development.”

Reed also highlighted the exceptional performance of solutions generated with GeneXus:

“The performance is excellent. And most importantly, none of the products we’ve developed with GeneXus have had critical bugs, crashes, or system failures.”

But perhaps the most powerful insight comes from his experience running a high-impact company with limited resources:

“Thanks to GeneXus, I’ve been able to maintain an extremely lean structure. Some clients think I have a large development team behind me, and that says a lot about what we’ve achieved. One client told me: ‘For a small company, you guys do huge things.’ And others, with internal teams, admitted they had spent six months trying to solve the same issue… and we delivered it in just days.”

With GeneXus and Globant Enterprise AI, you can automate, scale, and digitally transform your operations safely, without complexity or large development teams.

Request a personalized demo today and discover how to turn your logistics, traceability, or business management challenges into real competitive advantages.

The challenge

With over 19,000 transport units and a presence in refrigerated, flatbed, tanker, intermodal, and hopper load types, Prime Inc. moves thousands of vehicles daily. This constant movement inevitably results in the generation of large volumes of worn-out tires.To tackle this environmental challenge, Prime created EcoShred, a division dedicated to tire recycling. Its highly technical process includes:

- Primary Shredder: Converts used tires into 2- to 6-inch rubber chips.

- Secondary Line: Further reduces the chips into ¾-inch mulch nuggets, separating the steel.

- Coloring Line: Applies one of 10 available colors based on customer specifications.

This process turns waste into reusable products such as:

- Tire-Derived Fuel (TDF)

- Rubber aggregates

- Decorative mulch

- Industrial pellets

- Rubber powder

The problem

The machinery worked. The bottleneck was in the logistics management system. EcoShred coordinated tire collections using spreadsheets and whiteboards. The lack of real-time visibility and the high probability of human error hindered growth.“It was a slow system, prone to errors, and difficult to scale. We needed a more efficient way to work,” explains Michael Jones, EcoShred Manager.

The Solution: EASE + GeneXus = Transformation

The solution came from Information Services Select, a U.S.-based tech company specializing in ERP systems, which had already developed the EASE software for Prime using the GeneXus platform.EASE (Enterprise Automated Support Environment) was already successfully operating in EcoTire, Prime’s retreading unit, where between 35,000 and 40,000 tires are remanufactured annually, extending their lifespan up to 100,000 miles (160,000 kilometers).

But about 20% of tires are not suitable for retreading. That’s where EcoShred comes in - and where EASE proved its versatility.

What Does EASE Do?

EASE acts as a unified digital backbone, integrating:- Human Resources

- Customer Service

- Full Business Cycle Management (from order to cash)

Direct Impact on EcoShred

With EASE, EcoShred was able to:- Implement a centralized dashboard with real-time visibility.

- Automate pickups and deliveries.

- Eliminate the use of spreadsheets and whiteboards.

- Optimize the flow of recyclable materials.

- Apply precise color formulas per order.

“Now we see everything on a single screen, in real time. We don’t waste resources or money. We generate less waste, reduce costs, and save energy,” says Michael Jones.

The role of GeneXus: Unprecedented productivity and agility

EASE has brought a new level of clarity, control, and operational efficiency, aligning EcoShred’s daily work with Prime’s sustainability and waste reduction goals.EASE is a living, scalable platform deeply adaptable to each client's specific needs. And that’s made possible by GeneXus - the technology that has transformed how Information Services Select designs and delivers business solutions.

“With EASE managing these core activities, we can expand the platform more efficiently, adding customized functionalities that address specific business needs. The result is a highly tailored, cost-effective product focused on real value for the client,” explains James Reed, Director of Information Services Select.

Another remarkable aspect of EASE is that it was built by just two developers: one handled the core system functions, and the other expanded those foundations and created custom modules for different clients.

Today, over 1,000 users log into EASE daily, most from within the client environments themselves.

“Having a product like EASE lets me focus on the creative side, without diving into the technical details of every solution. For the client, that translates into a platform that allows them to focus on what really matters: growth, opportunities, and profitability,” says Reed.

Why did they choose GeneXus to develop EASE?

“In the past, I worked with a team of 14 developers. With GeneXus, I reduced that team to just 3 people and we were more productive than before using native code. We used the Java generator for EASE, and honestly, what would have taken me two years to develop in Java alone, I completed in just three months with GeneXus - and had a client already in production.”At a developer conference held in Chicago, Reed shared a striking example: 28 lines of GeneXus code equaled over 737 lines of native Java. Less code, more functionality - a quantum leap in efficiency.

“Back in 1991, I was looking for a tool to prototype what a client wanted, without spending weeks on something that might not get approved. I was introduced to GeneXus for its ability to generate functional prototypes that could be directly turned into real products. It was clear that it should be our platform for both prototyping and production development.”

What technical challenges did you face before using GeneXus?

“We didn’t have the agility to move from the AS/400 environment to Client/Server in the ’90s. GeneXus gave us that capability. The learning curve was minimal - the syntax across platforms was very similar, which saved time and resources. We didn’t have to retrain COBOL developers to learn Visual Basic. We already knew GeneXus, so we redesigned our screens, migrated the environment, and kept building from there.”What lessons can you share with other companies considering GeneXus?

“The big lesson is this: as long as you use GeneXus, you don’t need to learn new tools from scratch for each platform. Sure, there’s always something new to study, especially if you’re working with a new target environment. But in terms of code, GeneXus does most of the heavy lifting for you. It’s like securing the future continuity of your software without having to rebuild everything.”Reed also highlighted the exceptional performance of solutions generated with GeneXus:

“The performance is excellent. And most importantly, none of the products we’ve developed with GeneXus have had critical bugs, crashes, or system failures.”

But perhaps the most powerful insight comes from his experience running a high-impact company with limited resources:

“Thanks to GeneXus, I’ve been able to maintain an extremely lean structure. Some clients think I have a large development team behind me, and that says a lot about what we’ve achieved. One client told me: ‘For a small company, you guys do huge things.’ And others, with internal teams, admitted they had spent six months trying to solve the same issue… and we delivered it in just days.”

Take the Next Step: Transform your operations with GeneXus and Globant Enterprise AI

Does your company still rely on manual processes, outdated spreadsheets, or systems that don’t scale with your growth?With GeneXus and Globant Enterprise AI, you can automate, scale, and digitally transform your operations safely, without complexity or large development teams.

Request a personalized demo today and discover how to turn your logistics, traceability, or business management challenges into real competitive advantages.